Mobile Pneumatic Conveying System

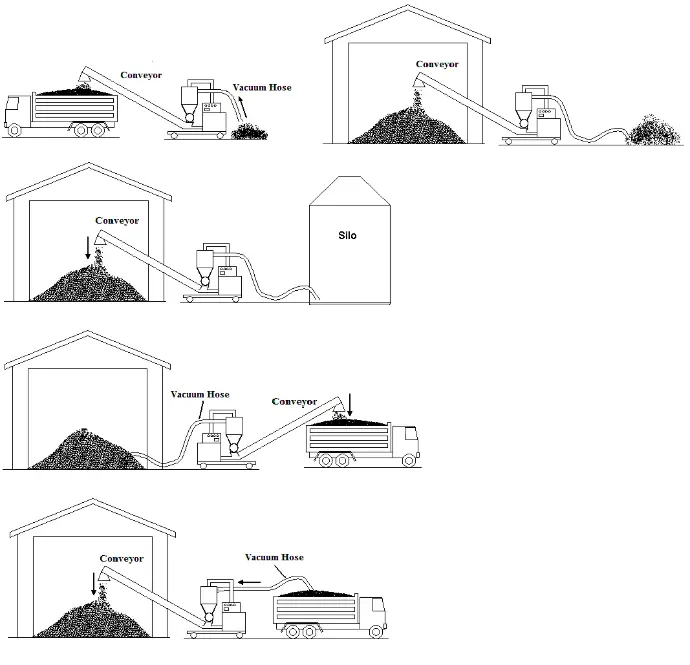

Polimak Mobile Pneumatic Conveying Systems are designed for efficient, dust-free, and flexible transportation of dry bulk materials using air or gas. Installed on a mobile chassis, these systems are ideal for temporary or multi-location use in industries such as food processing, chemicals, and pharmaceuticals. By reducing contamination risks and labor requirements, the system offers a sustainable and safe solution for handling bulk solids with minimal environmental impact.

How the System Operates

1. System Setup

• The mobile system is transported and positioned near the bulk material source or discharge point.

• All hoses and components are connected and powered up for operation.

• Operators ensure that containers, hoppers, or storage vessels are connected properly to receive conveyed material.

2. Material Feeding and Conveying

• A blower or compressor generates airflow, creating a vacuum that draws material into the conveying pipeline.

• The dry bulk material is transported through the pipeline using a powerful airstream.

• The system enables material transport using either suction or pressure, depending on the application needs.

3. Material Discharge Process

• The conveyed bulk material is directed into a cyclone separator or directly into a storage vessel.

• A rotary valve at the discharge point ensures consistent and regulated material flow.

• The bulk material is dishcharged into the container (e.g., silo, hopper, or mixing tank) in a dust-free manner.

4. Dust Control and Clean Operation

• Dust generated during conveying is captured by an integrated dust collection unit.

• Collected particles can be reintroduced into the process, minimizing product loss.

• The enclosed system prevents dust emission, maintaining a safe and clean workspace.

5. Process Completion

• Once material transfer is complete, the system stops the airflow and seals the discharge point.

• The unit can then be relocated for the next operation or switched to standby mode.

• Minimal cleaning and maintenance allow for fast turnaround between applications.

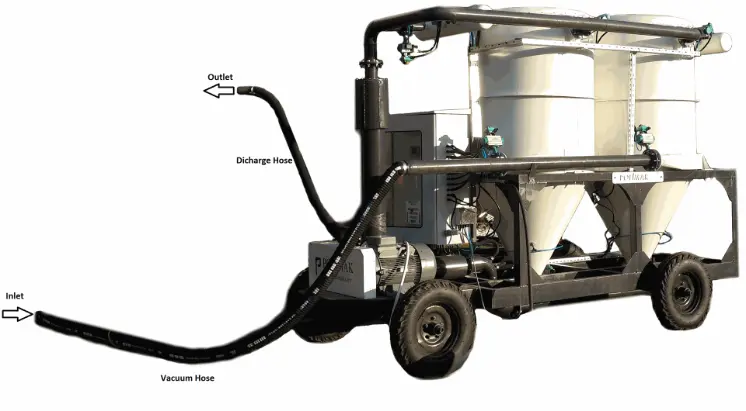

Components of the System

Mobile Chassis

• A robust, transportable platform that supports all conveying components.

• Easily moved using forklifts, trailers, or tow arms.

• Suitable for indoor or outdoor applications and rapid setup.

Blower or Compressor

• Provides the air pressure or vacuum needed to convey materials through the system.

• Built for continuous operation and capable of handling different materials over varying distances.

Conveying Pipeline

• Air-tight piping system that transports bulk solids between source and destination.

• Configurable in length and layout for different site conditions.

• Manufactured from durable materials to withstand abrasive or corrosive products.

Rotary Valve

• Regulates the rate of bulk material discharge at the end of the conveying line.

• Ensures smooth and consistent flow into hoppers, silos, or processing machines.

• Prevents backflow and maintains pressure integrity in the system.

Cyclone Separator

• Used to separate conveyed material from the air stream before final discharge.

• Enhances efficiency and reduces product loss.

• Preferred in applications with fine or powdery materials.

Dust Collection System

• Captures airborne particles generated during conveying.

• Helps maintain regulatory compliance and protects operator health.

• Reduces cleanup time and promotes sustainability by recycling material.

Highly Mobile

Designed for easy transport across various locations within the facility.

Dust-Free Operation

Enclosed system minimizes airborne contamination.

Efficient and Clean

Reduces manual handling, spillage, and product loss.

Safe for Sensitive Materials

Enclosed bulk material transfer protects product purity.

Flexible Configuration

Suitable for a wide range of industries and material types.

Sustainable

Built-in dust control reduces environmental impact and enhances material recovery.

Cost-Effective

Optimized transfer process reduces labor, downtime, and maintenance.