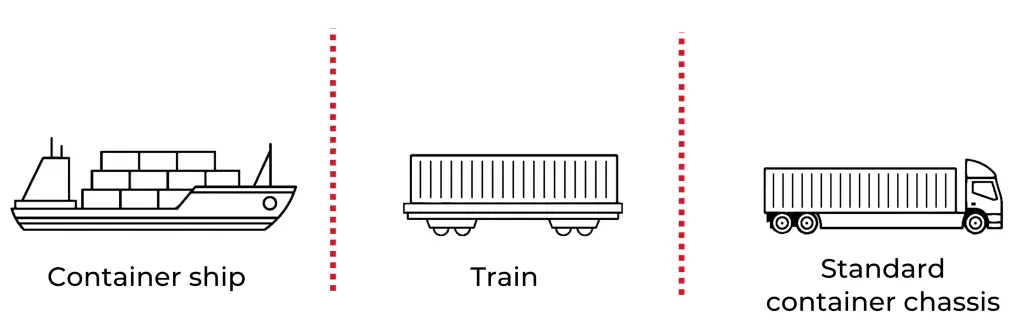

Intermodal Transfer (Ship – Train – Truck)

Intermodal transfer systems are fundamental to modern port and container terminal operations. These systems enable the direct and efficient movement of containers or bulk materials between ships, trains, and trucks, minimizing manual handling, reducing transit times, and improving logistical coordination.

By focusing on containerized and bulk cargo transfers, ports can streamline operations, reduce costs, and enhance sustainability. Intermodal solutions are especially needed in high-volume handling operations where timing and coordination between different transport modes are critical.

How the System Operates

• Vessel Unloading: Containers or bulk cargo are first offloaded from ships using gantry cranes, mobile harbor cranes, or continuous ship unloaders, depending on the cargo type.

• Mode Selection & Routing: Cargo is automatically transferred toward either rail or road depending on the delivery schedule, cargo destination, and availability of inland transport resources.

• On-Dock Rail Transfer: If destined for rail, containers or bulk materials are moved to on-dock rail terminals using yard tractors or automated guided vehicles (AGVs), then loaded onto wagons using reach stackers or automated rail-mounted gantries (RMGs).

• Truck Transfer: For road delivery, cargo is loaded onto trucks at designated loading bays or via side-loaders. Weight and ID checks are often integrated via automated gate systems.

• Smart Coordination Systems: Real-time yard management systems (YMS) and terminal operating systems (TOS) ensure efficient scheduling, traffic control, and communication between ship, train, and truck operations.

Key Components

• Gantry Cranes & Mobile Harbor Cranes: Essential for lifting containers or cargo from ships and transferring them to land-based systems with high speed and precision.

• Yard Transfer Vehicles (AGVs or Terminal Tractors): Automated or semi-automated vehicles that move containers or cargo from ships to rail or truck loading zones.

• Rail-Mounted Gantry Cranes (RMGs): Used in on-dock rail operations to load and unload cargo from railcars efficiently, often with minimal human intervention.

• Truck Loading Bays: Specialized, optimized areas equipped with lifting gear, safety equipment, and sometimes automatic container loaders for road-bound cargo.

• Logistics Software Integration: Advanced tracking and management platforms that synchronize movement across all modes and allow real-time tracking, route optimization, and exception handling.

Key Advantages and Benefits

• End-to-End Supply Chain Integration: Intermodal systems enable continuous bulk material transfer between sea, rail, and road without unnecessary delays or handling.

• Cost Optimization: Reduces operational costs by minimizing cargo retention time and eliminating redundant handling steps.

• Environmental Efficiency: Encourages modal shift to rail, a more fuel-efficient option that produces lower emissions compared to long-haul trucking.

• Increased Port Throughput: Efficient cargo transfer reduces port congestion and enables quicker ship turnaround times, increasing overall terminal productivity.

• Flexibility and Scalability: Intermodal systems are adaptable to cargo type, volume, and port infrastructure, making them suitable for small terminals and mega ports alike.

Industry-Specific Examples

• Agricultural Export Hubs: Containers filled with agricultural products such as soybeans are discharged from ships and transferred by AGVs to an on-dock rail terminal. They are moved inland to processing plants within hours. This streamlines the entire farm-to-port-to-plant logistics chain.

• Industrial Raw Materials Supply Chain: Industrial raw materials scuh as iron ore is discharged from ships into hoppers and loaded directly into railcars using high-capacity conveyor systems. This approach reduces the need for ground storage. It also minimizes material loss and handling time.

• Chemical Logistics Corridors: Hazardous chemicals are containerized at the origin and moved seamlessly from ship to train. The process is tightly regulated, with RFID tracking and automated documentation. These systems ensure safety, traceability, and compliance.

• Construction Mega Projects: Cement, steel, and other construction materials are transferred from port to rail, then onto trucks for final delivery. GPS-coordinated scheduling ensures timely arrivals at remote job sites. Container tracking supports efficient inventory and logistics management.