Containerized Transportation

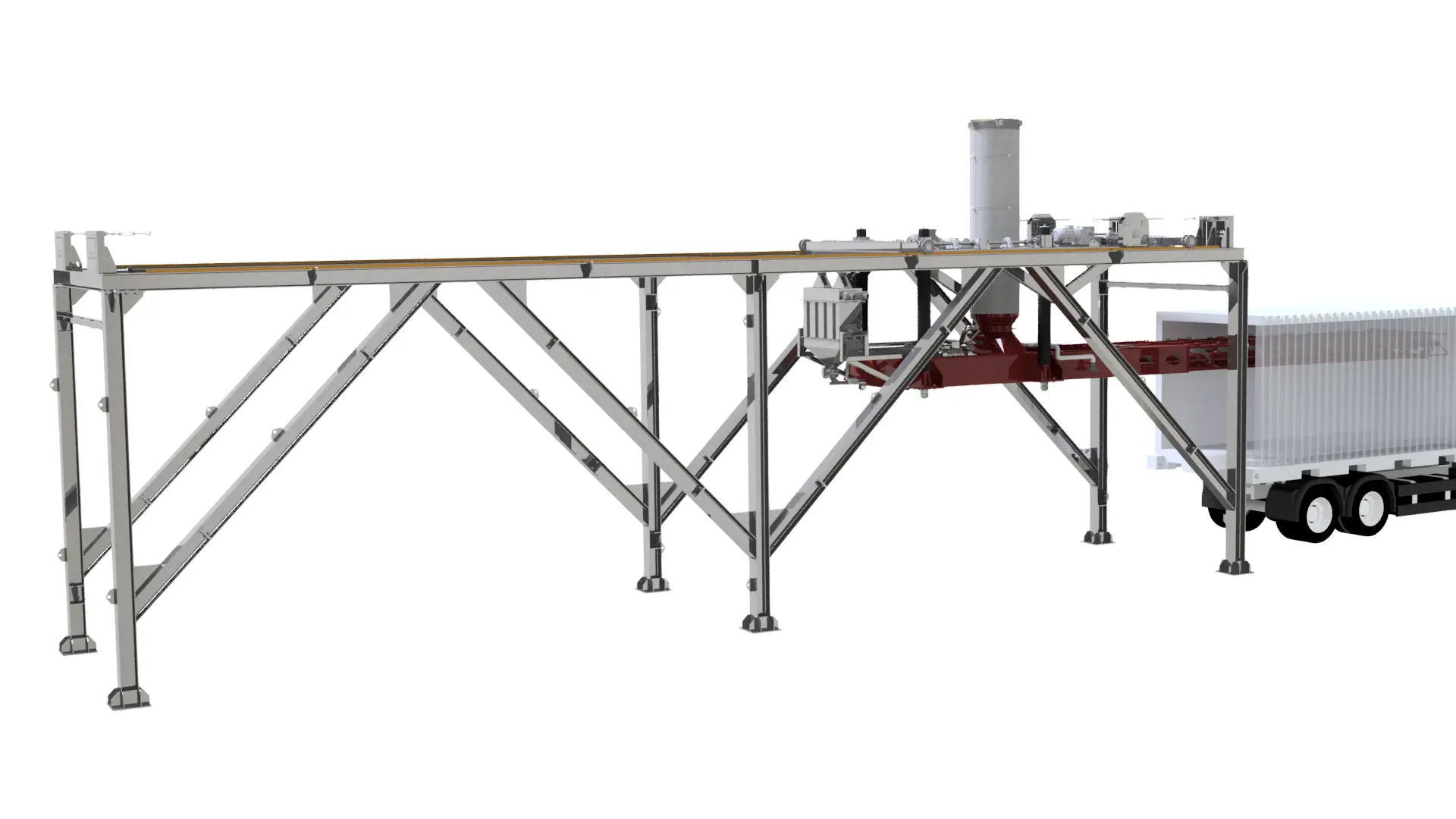

Polimak’s innovative containerized transportation solutions transform the bulk handling industry by providing an efficient system for loading and unloading hard-to-flow and lightweight materials. Equipped with a floating floor system and discharge frame, it allows for smooth unloading from containers without the use of tilting trucks.

The system utilizes a rotating drum to pull the sliding floor of the liner bag, pushing the material toward the outlet without the need to tilt the container. The material then smoothly flows into the discharging hopper. An integrated conveyor transports the material from the hopper to downstream systems, such as silos or processing lines, ensuring efficient and seamless integration with existing operations.

This cutting-edge technology guarantees a safe, reliable, and dust-free discharge process, significantly reducing material handling complexities throughout the supply chain.

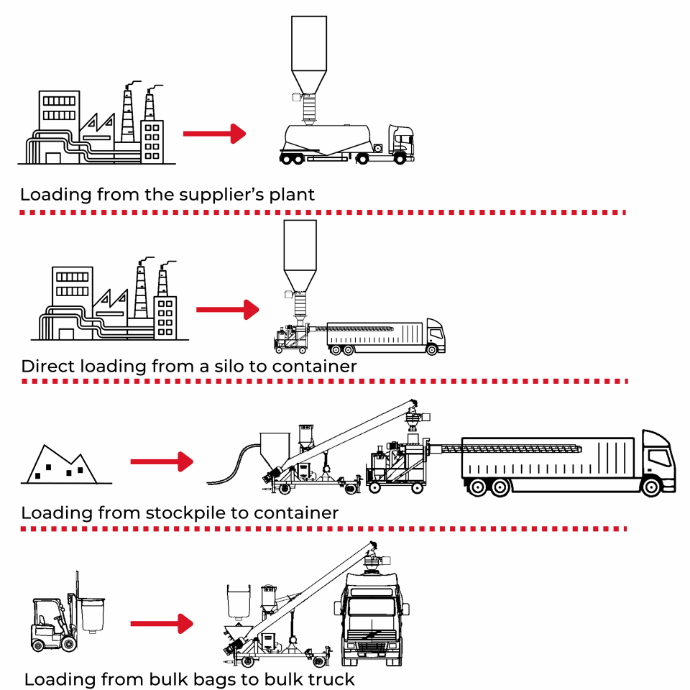

1. Loading

You can utilize the loading method according to your needs:

- Loading from the plant;

- Direct loading from a silo to a container;

- Loading from a stockpile to a container;

- Loading from bulk bags to a bulk truck.

Our innovative solutions offer a range of loading alternatives tailored to handle even the most challenging bulk materials.

Whether it's through vacuum technology, conveyors, or specialized equipment, Polimak provides versatile solutions that ensure efficient and reliable bulk solid transfer.

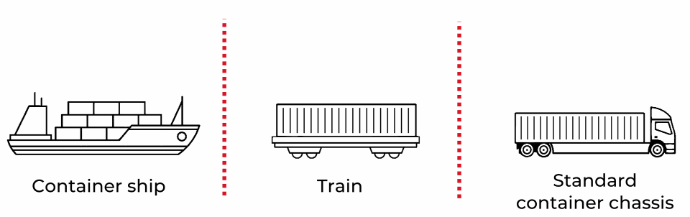

2. Main-Carriage

The product is then transported via container shipping, short-sea shipping, train, or standard container chassis, by choosing the most efficient mode of transport.

Transport your bulk solid material in standard ISO containers.

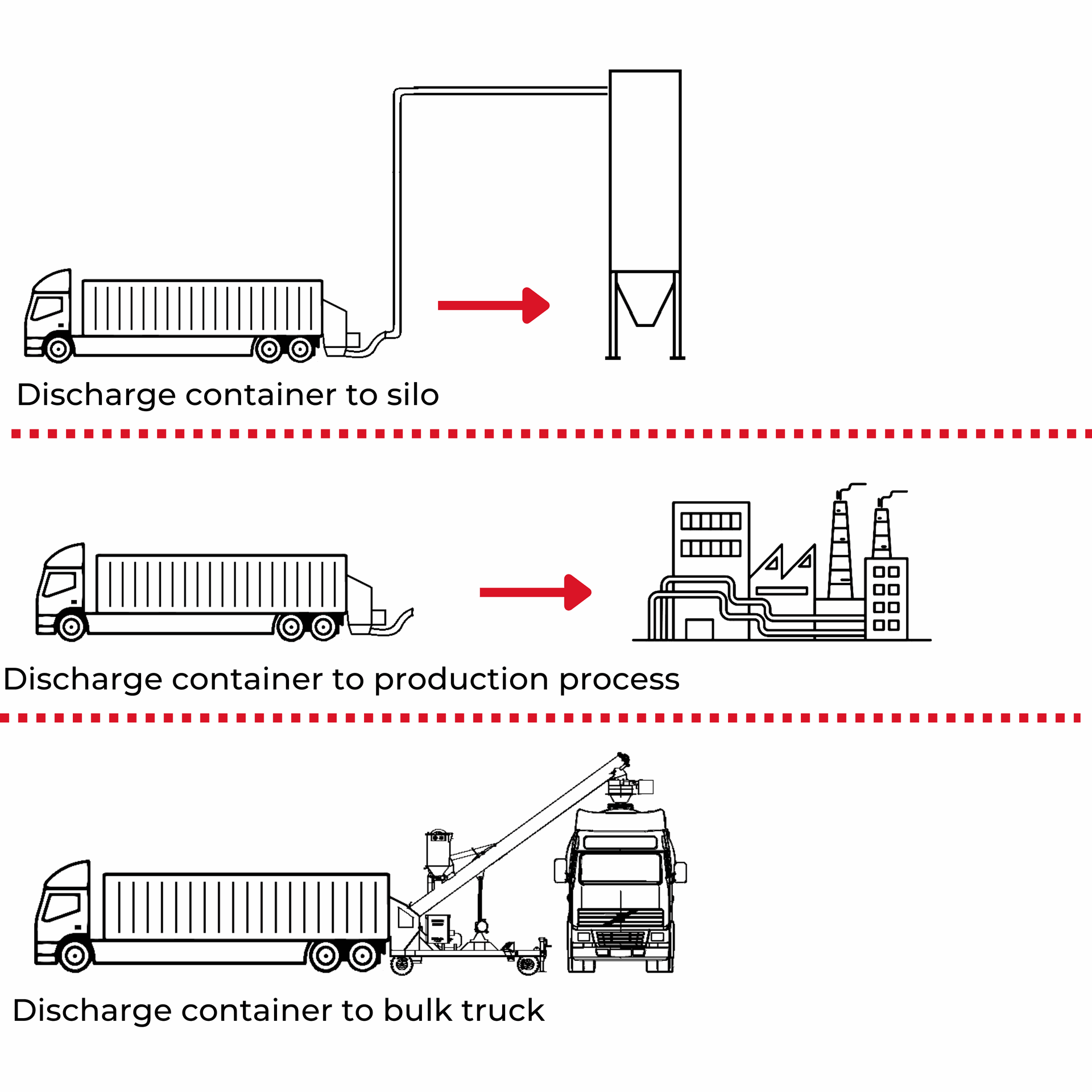

3. Unloading

After arriving at the final destination, the product is unloaded safely using mechanical, horizontal conveying. According to the customer's needs, the unloading can be carried out in the following ways:

- Discharging the container directly to a silo;

- Discharging the container to a further production process;

- Discharging the container to a bulk truck.

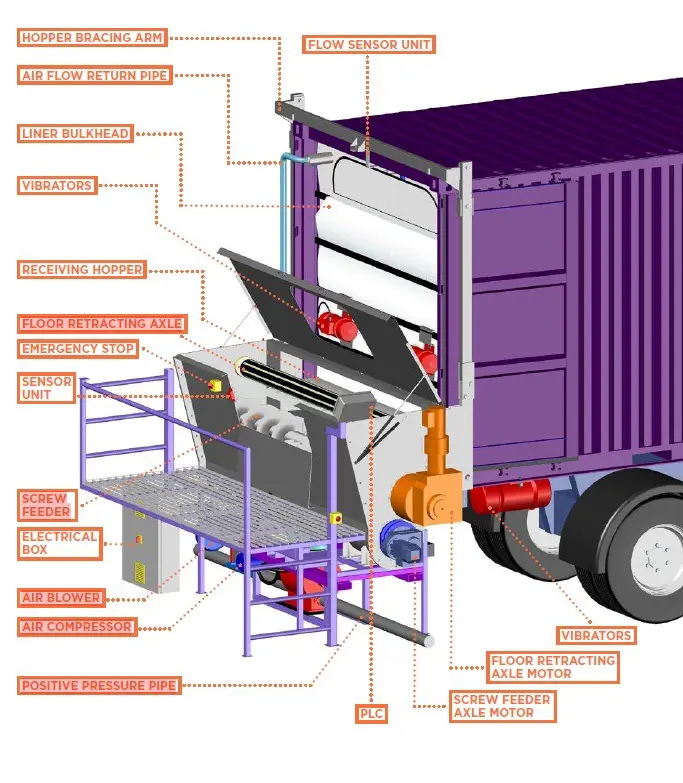

Components of the System:

· Hopper Bracing Arm: Supports the hopper structure to ensure stability during bulk material discharge.

· Air Flow Return Pipe: Returns air back to the system to maintain proper airflow balance.

· Liner Bulkhead: Internal wall of the liner that helps guide material flow and provides structural support.

· Vibrators: Mechanically shake or vibrate the liner to help bulk material flow smoothly and prevent flow-related issues such as clogging and ratholing.

· Receiving Hopper: Collects discharged bulk material from the liner and directs it toward the screw feeder.

· Floor Retracting Axle: A floor-actuation mechanism that facilitates material discharge and enables tilt-free unloading

· Emergency Stop: A safety mechanism designed to instantly stop all operations during an emergency situation.

· Sensor Unit: Monitors critical parameters to ensure safe and efficient system operation:

- Material presence

- Material flow

- Position of moving parts

Sensors continuously track these parameters, triggering alarms or shutting down components if abnormalities or safety issues are detected.

· Screw Feeder: Rotating screw mechanism that moves bulk material from the receiving hopper to the discharge pipe.

· Electrical Box: Houses all electrical controls, relays, and wiring connections for system operation.

· Air Blower: Provides air flow needed for pneumatic movement or to assist in material discharge.

· Air Compressor: Supplies compressed air to power pneumatic components and maintain system pressure.

· Positive Pressure Pipe: Provides a controlled stream of pressurized air to enable the flow of bulk material through the system.

· PLC (Programmable Logic Controller): Controls and automates system operations, receiving input from sensors and sending commands to motors and other actuators.

· Flow Sensor Unit: Measures the flow rate of bulk material moving through the system to ensure consistent operation.

· Floor Retracting Axle Motor: Supplies mechanical power to actuate the floor-retracting axle mechanism, enabling controlled movement of the floor during discharge.

· Screw Feeder Axle Motor: Drives the screw feeder mechanism, ensuring consistent movement of material from the hopper through to the output.

Key Advantages of Containerized Transport for Bulk Solids

- Maximize Payload Efficiency per Shipment

- Optimizes the use of available cargo space to ensure every shipment carries the highest possible volume.

- Reduces the number of trips required, reducing overall transport costs.

- Enhances operational efficiency by maximizing vehicle load capacity.

- Dust-Free Loading Process

- Significantly reduces the release of fine particles into the air during loading and unloading.

- Provides a cleaner working environment, enhancing worker safety and minimizing health risks.

- Reduces material loss caused by dust dispersion, preserving product quality.

- Minimization of Particle Degradation

- Ensures bulk materials remain intact and undamaged during transport.

- Prevents quality loss by avoiding excessive handling or multiple transfers between different transport modes.

- Provides consistent protection for sensitive goods with specialized container liners.

- High Output and Energy-Efficient Operations

- ISO containers offer a reliable and cost-effective storage and transport solution for bulk commodities.

- Supports cost reduction by applying energy efficient methods for loading and unloading.

- Enables higher material flow rates, supporting industries with large-scale, continuous operations.

Maximum Cargo Load in Each Shipment

Efficient cargo space utilization.

Dust-Free Loading Process

Reducing the air-to-particle ratio.

Less Particle Degradation

Enhanced particle quality by avoiding transfer between different modes of transportation.

IDEAL BULK SOLIDS FOR CONTAINER TRANSPORTATION

White Cement

Calcium Carbonate (CaCO₃)

Flour

Starch

Zeolite

Aluminum Oxide (Al2O3)

Sugar

Salt

Grains

Coal

Cocoa Powder

Fly Ash