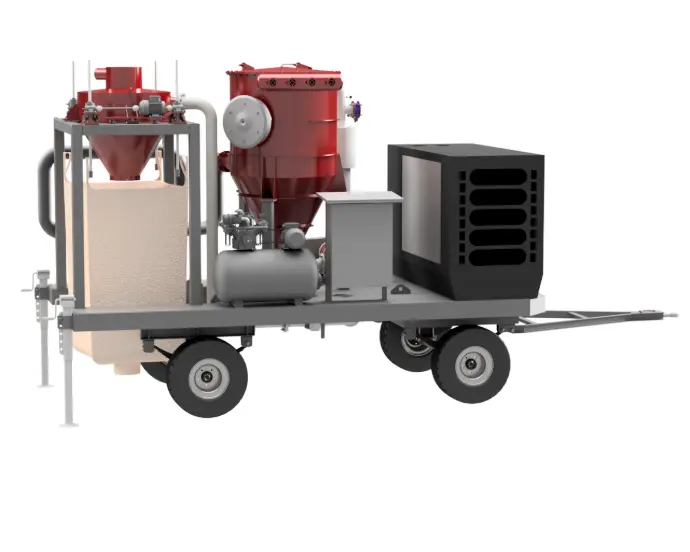

Mobile Bulk Bag Filling Systems

Polimak Mobile Bulk Bag Filling Systems are designed for efficient, dust-free, and safe filling of big bags or octabins, with the added flexibility of mobility. These systems are ideal for temporary or on-site operations and promote sustainability by minimizing material loss and improving clean handling of bulk solids. Typical users include industries such as chemicals, food, plastics, and agriculture.

How the System Operates

1. System Setup

• The mobile unit is transported and positioned at the designated filling location.

• All system components are connected and powered for operation.

• Operators ensure that empty big bags or octabins are correctly placed under the filling spout.

2. Material Feeding and Conveying

• Bulk material is vacuumed by a blower or vacuum pump from a source (e.g., silo, container, or stockpile).

• The bulk material is pneumatically conveyed through the pipeline system to a cyclone separator.

• The cyclone separates the bulk solid from the air stream, collecting the product inside its chamber.

3. Bag Filling Process

• Bulk material collected in the cyclone is discharged into a big bag or octabin.

• A rotary valve ensures a consistent and controlled flow of bulk product into the container.

• The system continues filling until the desired weight or fill level is reached.

4. Dust Collection and Recyclability

• Dust generated during the filling process is captured by an integrated dust collector system.

• Collected particles are returned to the cyclone, reducing material waste and ensuring clean operation.

• This enclosed system improves efficiency and helps maintain a dust-free environment.

5. Process Completion

• Once the big bag is filled, the rotary valve stops the product flow.

• The filled bag is sealed and removed.

• The system can then be repositioned or prepared for the next filling cycle.

Components of the System

Mobile Chassis

• Houses the entire filling system on a reliable, movable platform.

• Can be easily transported using forklifts, trucks, or towbars.

• Ensures flexibility in on-site operations and outdoor environments.

Blower or Vacuum Pump

• Provides the airflow required to transport bulk material to the cyclone.

• Designed for reliable, continuous operation across different material types.

Cyclone Separator

• Separates the bulk solid from the conveying air stream.

• Collects product efficiently before it is discharged into the big bag.

• Ensures minimal product loss and reliable separation performance.

Rotary Valve

• Regulates the discharge of material from the cyclone to the big bag.

• Provides consistent and accurate flow, preventing surges or spillage.

• Necessary for precise bag filling operations.

Big Bag Filling Spout

• Conveys material into the bag or octabin with minimal dust emission.

• Can be equipped with bag clamping systems for a tight, dust-free seal.

• Adjustable to accommodate different bag sizes.

Dust Collection System

• Captures airborne dust during conveying and filling process.

• Returns collected particles to the system to reduce waste.

• Maintains a clean and safe work environment.

Mobile and Flexible

Easily transported and deployed at different work sites.

Dust-Free Operation

Advanced dust collection ensures clean and safe bag filling solution.

Efficient Material Handling

Continuous, controlled flow reduces spillage and waste.

Contamination-Free

Sealed design prevents contamination during the filling process.

Environmentally Friendly

Recycles dust particles back into the system, minimizing material loss.

Versatile Industry Applications

Suitable for use in chemical, food, plastics, agriculture, and more.

Cost-Effective

Reduces material waste and manual labor, increasing overall productivity.